Your advantage

|

Why should nitrogen

losses be limited during manure application? |

|||||||||||||||

|

·

Nitrogen losses are harmful

to the environment. ·

Nitrogen losses are

expensive: They increase the need for synthetic fertilizers. |

|||||||||||||||

|

|

|||||||||||||||

|

On what do the nitrogen

losses mainly depend? |

|||||||||||||||

|

Most farmers believe that the maximum nitrogen

loss during manure application occurs while the manure is flying through the

air. But actually, the evaporation occurs primarily in the time between the

application and the infiltration/incorporation of the manure into the soil

(see Graph

1, Graph

2). |

|||||||||||||||

|

An important objective of manure spreading is

therefore to slow down the evaporation. To this end, on the one hand a more

favorable time for applying the manure should be selected (ideally: low

temperatures, little wind, shortly before precipitation/incorporation into

soil). On the other hand, appropriate technology should also be employed. The

most well-known and effective technique for this is to apply manure with drag

hoses. The surface of the manure is greatly reduced and the evaporation

process is slowed down. It is still little known that this effect is also achieved

with the MOESCHA swivel spreader. |

|||||||||||||||

|

|

|||||||||||||||

|

How does the MOESCHA

spreader help to minimize Nitrogen losses? |

|||||||||||||||

|

Because of the geometric shape of the

swiveling head and because of the deflection of almost the entire manure

stream, the patented MOESCHA swiveling spreader forms very large drops. The

bigger the drops, the better the nitrogen is protected from evaporation. Cube

example: |

|||||||||||||||

|

|||||||||||||||

|

As a consequence: Drops that are twice as

large, yield half the drop surface per unit of manure and, thus,

significantly less nitrogen evaporation. |

|||||||||||||||

|

|

|||||||||||||||

|

Large drop manure

application via patented swivel spreading |

|||||||||||||||

|

(detailed

view by clicking on the figure) |

|||||||||||||||

|

|

|||||||||||||||

|

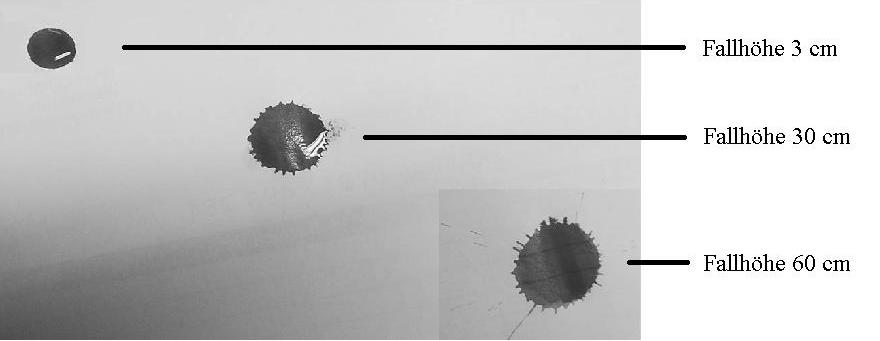

However, in order for the manure also to come

to rest on the ground in the form of large drops, its impact speed must not

be too high. The following graph makes this clear: |

|||||||||||||||

|

|

|||||||||||||||

|

With the MOESCHA swiveling spreader, the drops

are released with reduced speed in an almost horizontal direction: |

|||||||||||||||

|

·

Exit speed at the nozzle:

11.6 m/sec corresponds to 42 km/h ·

Exit speed from the

swiveling head: 8 m/sec corresponds to 29 km/h |

|||||||||||||||

|

This is a clear advantage over impact

spreaders, because only in this way is a large-drop spreading pattern

produced and, thus, a slowing of the nitrogen evaporation. |

|||||||||||||||

|

|

|||||||||||||||

|

What further advantages

does large-drop MOESCHA manure spreading provide? |

|||||||||||||||

|

Because of the reduced surface and because of

a better ratio of weight to surface, there is clearly better spreading even

in the presence of crosswinds (see DLG test). In addition, the wetting/soiling of the plants

and, thus, damage to them is clearly reduced. The company MOESCHA therefore

recommends applying manure in pastureland at a crop height of approximately

10 cm. The soiling of the leaves is minimal and the nitrogen losses can once

again be sharply reduced (protection of the manure from sun and wind). |

|||||||||||||||

|

|

|||||||||||||||

|

Conclusion: The MOESCHA

spreader is above all the best solution for grassland! |